This article aims to explain terms such as 3D printing technology, the principles of 3D printer operation and 3D printing methods.

What is 3D printing?

3D printing is one of the 4 important steps of a closed process, going from 3D Scanning – Reverse engineering – 3D printing – Quality control. 3D scanning helps to quickly measure and collect 3D data of the object. Reverse engineering helps quickly recover 3D CAD blueprints from real objects. 3D printing helps to quickly produce prototype products from blueprints of reverse engineering. Finally, Quality Control verifies that the accuracy of the sample product meets the original design.

3D printing is defined as “the process of creating three-dimensional objects through the method of deposition and processing of materials in layers, using computer-assisted devices” (Lam et al (2002) [1]) .

It’s hard to understand, isn’t it? Imagine placing a piece of paper on the table. It is a slice (layer) in 2D, because it only has length (length) and width (width). Imagine you put a lot of paper stacked on top of each other, it will form 3D objects (length-width-height). That is the simplest principle of 3D printing technology.

History of 3D printing technology:

- The first rapid production technology was developed in 1981

-

The father of this technology is Hideo Kodama of Nagoya City Institute of Technology Research.

-

The first Additive Manufacturing technology was developed as SLA, a technology that uses thermoset plastics, a plastic that will change from liquid to solid when exposed to high heat sources, such as a laser beam.

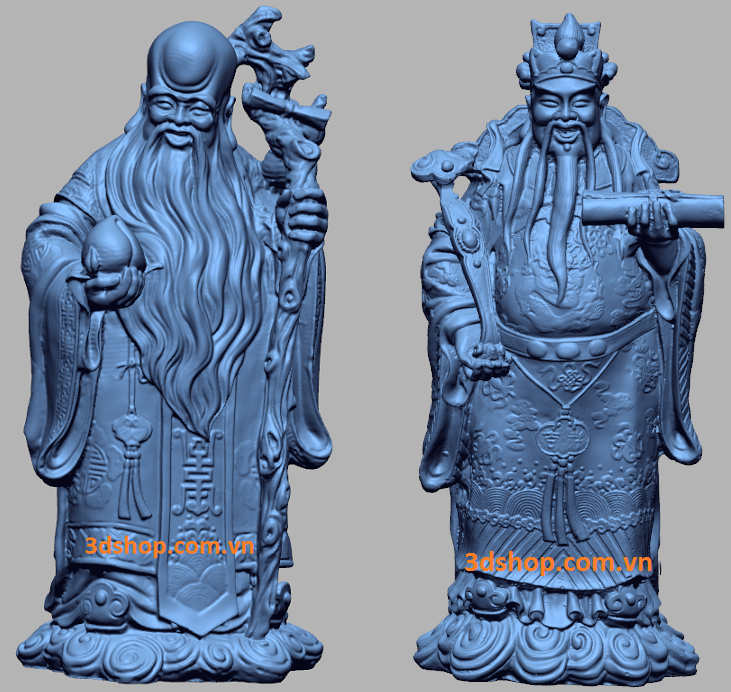

Application of 3D technology:

3D Printing in Manufacturing:

- Advantages: flexible shaping ability

-

Application: creating molds for the casting industry, creating prototype products before mass production, …

3D printing in the Military:

- Shorten production costs to 20% and reduce time to 10%

-

Production of military equipment such as missiles, submarines, …

3D printing in Health:

- Make high-precision copies of organs (bones, hearts, lungs, etc.) based on CT scans

- Create prosthetic limbs, accessories to support injury recovery

- Modeling porcelain teeth, titanium with high precision and shaping identical teeth.

3D printing in fashion:

-

Create details of dresses, pants, skirts, ..

-

Manufacture all kinds of jewelry.

- There is still a long way to go due to technical difficulties (a shirt needs 100 hours to produce)

3D printing methods:

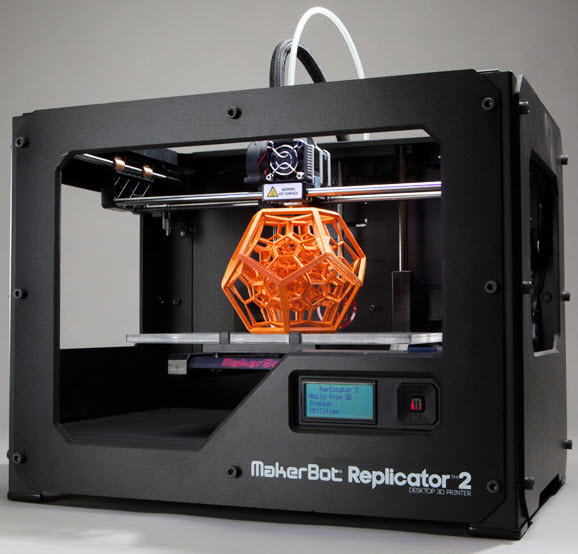

FDM/ FFF:

- Popular 3D modeling method and the lowest cost

-

Use the method of fusing plastic yarn and covering the layer through the nozzle

-

Each layer of melted plastic will stick to the previous printing layer, becoming a 3D printed pattern

SLA:

- Pioneer printing method

-

Use thermoset polymers (liquid thermosets)

-

Use a heat source (laser light) on the plastic tub to create a printed shape in layers

DLP:

- Similar to SLA

- Replace the heat source with LED lights

-

Scan through the print tank correctly, should have a much higher print speed than SLA

Laser Sintering/Laser Melting:

- 3D modeling materials in powder form

-

Laser projection to link the material particles into solid blocks, in layers

-

When a printing layer is completed, the next layer of flour is brushed off for further processing.

Inkjet: Material Jetting:

- Use thermoset thermoplastic material nozzles

- UV treatment to become solid

- Can combine multiple materials to enhance the properties of the materials

;

;

;

;

;

;