What is reverse engineering? How is reverse engineering applied? How is reverse engineering applied? How is reverse engineering of mechanical products different from other products? Perhaps this is the question of many people but has not been answered satisfactorily. So today, let 3DShop help you to answer those questions.

- What is reverse engineering?

- Reverse engineering process.

- Application of reverse engineering of mechanical products.

- Application of reverse engineering of mechanical products

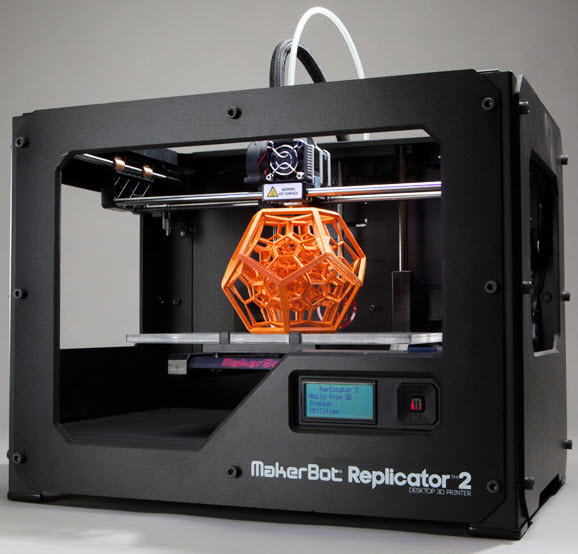

Previously, to design anything, engineers had to spend a lot of time measuring and calculating. If the specimen has many small details, this becomes even more difficult and the error increases. Therefore, engineers are always looking for a technology that can help them shorten design time. The advent of 3D scanner has brought a much more efficient and accurate measuring solution. 3D scanners help digitize data, engineers use that data to reverse engineer.

1. What is reverse engineering?

There are many different concepts about reverse engineering, but in the field of mechanics you can roughly understand: Reverse Engineering is the process of building a design model on specialized software through digital data. The most common of these are 3D scanners and CMMs.

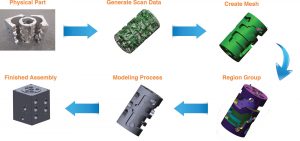

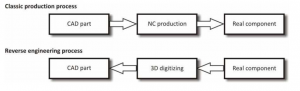

2. Reverse engineering process

As its name suggests, reverse engineering is the opposite of the traditional design process. If with the traditional method, engineers will follow the process. N hu bridge design ideas create a prototype check product. Then with reverse engineering the process will be as follows. Sample products scan for data create prototypes and test product.

- Coordinate measuring machine: CMM machine (contact point coordinate measuring machine), 3D scanner (non-contact point coordinate measuring machine).

- Design Software: The most popular and best is Geomagic Design X: the mesh (3D Scan) editing software. There are also a number of other CAD software like Solidworks, ProE, Catia and NX.

3. Advantages of reverse engineering

Reverse engineering has many advantages, including:

- First of all, this method helps to reduce difficulties when designing specimens with high geometrical complexity or free-bound, free-edge (non-forming) specimens. This allows for faster and more accurate specimen design.

- Do you think that samples with twisted surfaces such as turbine blades, aerodynamic and hydrodynamic surfaces will be difficult to measure data? Yes, definitely. With surface designs that have shaping laws but cannot determine the above design parameters, reverse engineering is also very effective.

- In fact, reverse engineering is used in many fields such as fashion, education, construction, manufacturing, medicine, …

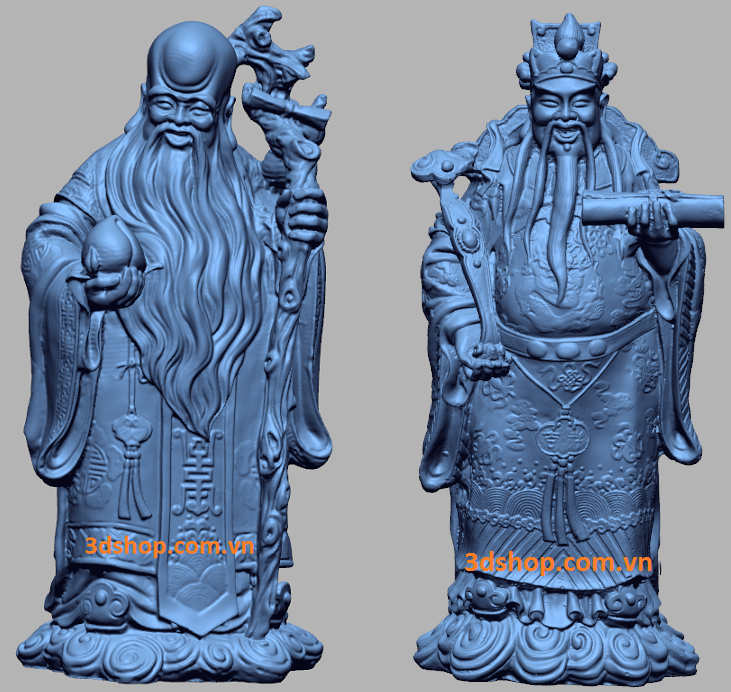

4. Application of reverse engineering of mechanical products

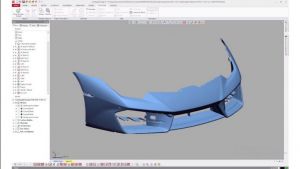

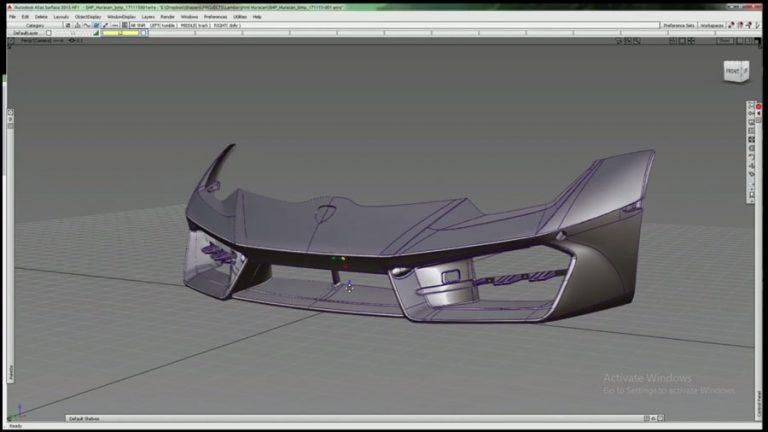

The reverse engineering approach is playing an important role in the rapid prototyping process. Large companies are investing in reverse engineering to shorten prototyping time. At the same time, to reduce the time required to produce real products, thereby increasing competitiveness. In the automotive industry, reverse engineering is used in many steps combined with 3D printing:

- Step 1: Create the style

- Step 2: Quick prototyping

- Step 3: Scan samples to get data

- Step 4: Reverse engineering:

- Step 5: Test and finished product

>> You can see more articles about “Reverse engineering of car brakes” here

Thank you for reading the article: “Reverse Engineering: What You Should Know?” If you are looking for the best reverse engineering service provider in Hanoi. Please contact us at the address below:

Smart Design Labs Co. Ltd

3D PRINTER – 3D PRINTING PLASTIC – 3D PRINTING SERVICES 3D

SCAN – 3D SCAN

SERVICES

🏠Address: 86 Le Trong Tan – Thanh Xuan – Hanoi

☎️ Tel: 024.7300.7070

☎️Hotline: 083 4400 810 | 0358736772

👉Facebook: Smart Design Labs Co. Ltd

📧Email: contact@3dshop.com.vn

🌐Facebook: 3DShop Vietnam

;

;

;

;

;

;